The Fan Jet Plus has all the features of the standard Fan Jet Pro in terms of spreading performance, headland control and options, although variable disc speed is standard.

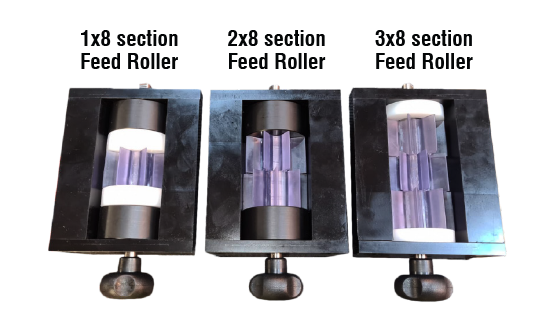

However, Plus models use a rotary feed mechanism, instead of a gravity feed, onto the spinning disc. Fluted feed rollers are driven by an electric motor, and the choice of feed roller and speed of rotation determines the application rate. A rotary feed allows very low application rates to be used without risk of blockages.

The Plus can also be mounted on most 12v agricultural machines with the exception of a quad bike due to its weight and power requirements.

The disc speed can be ‘dialled up’ or down to adjust the spreading width, for example to match the implement width, when used to broadcast small seeds to minimise damage (OSR, turnips, etc).

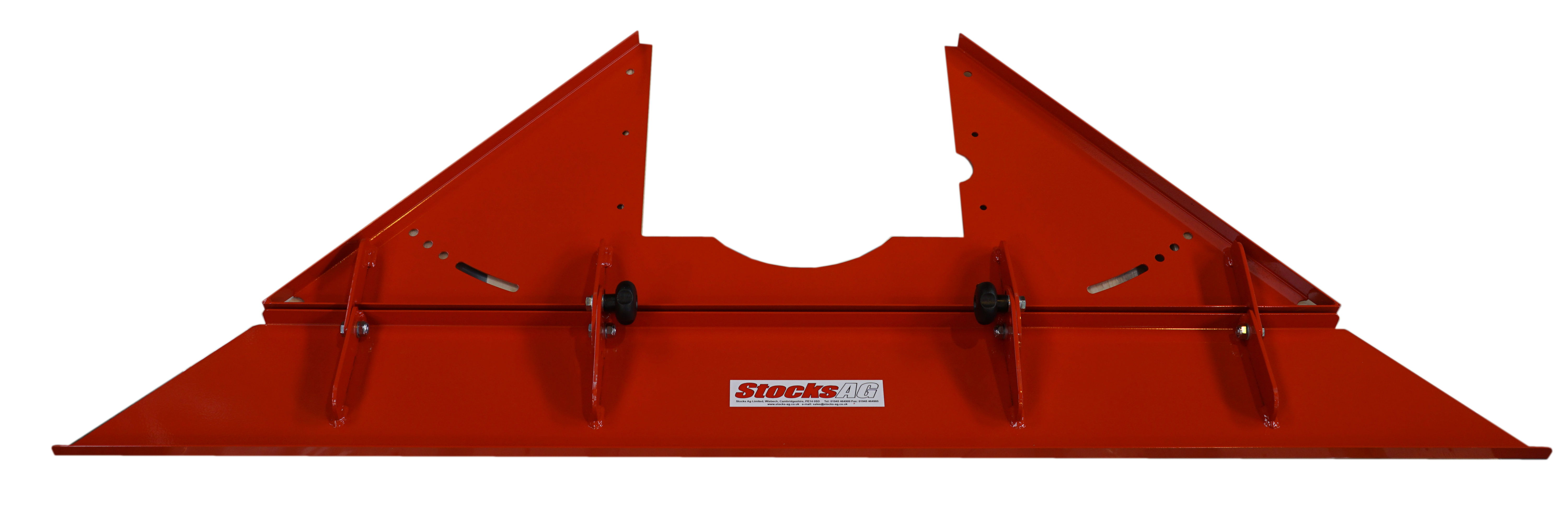

Simple design, proven over many years combined with robust welded construction.

KEY FEATURES

- Spread width up to 24m

- Adjustable speed related application with JACKAL and i-CON

- Easy, quick, stepless adjustment of bias left or right

- Easy emptying of hopper

- Adjustable deflectors to limit spread width

- Disc speed adjustment to limit spread

- Mostly used on sprayers or UTVs

- 3500 rpm disc motor

- Stainless steel twin-vane spinning disc

- Electric motor adjustment of application rate

- 12v 20A power requirement

- In cab electric controls. Instant feed shut off

- 5m fused power and 6m connector cable included

- Robust construction with high-quality motors

- 65 or 130 litre plastic hopper

- Optional grass seed deflector

- Optional feed rollers available

FAN JET PLUS CONTROLS

THREE CONTROL OPTIONS

VARI-SPEED CONTROL

Disc speed and feed roller speed can be changed on

the move from the tractor seat using a simple dial control.

A simple and effective manually operated electric control is used to instantly start and stop the feed motor e.g. at headlands.

- Left hand switch - disc motor on/off

- Left hand dial - disc motor speed control

- Right hand switch - feed motor on/off

- Right hand dial - disc motor speed control

JACKAL CONTROL

The JACKAL is a simple compact controller which enables monitoring and adjustment of all key functions. Screen shows application rate, forward speed, hopper level alarm and fan voltage. As standard the forward speed input is taken from the tractor 7 pin implement socket, a GPS speed sensor is optional.

- Large LCD screen and robust water resistant housing

- Quick easy set-up

- Simple accurate calibration for precise rate control

- Forward speed related rate control as standard with on the move adjustment

- High and low alarms for fan and metering roller

- Multiple trip counters and live date scrolling

i-CON CONTROL

Rates are automatically controlled in proportion to forward speed for ultimate accuracy, and the machine can apply variable rates according to mapping data using a GPS based touch screen*.

*subject to unlock fee

- 4.3” colour touch screen with 4 basic menu keys

- Seed application rate kg/ha

- Rate nudge - on the move adjustment in pre-set increments

- Min/max forward speed (km/h) indicator with alarms

- Metering unit status (on/off) and alarm

- Disc status (on/off) and alarm

- Hopper contents (kg) and low level alarm

- Part, full job & grand totals for area (ha), product dispensed (kg) and hours worked

SPREAD WIDTH

Quoted spread widths are only a guide. The density of product diminishes towards the extremity and so an overlap is recommended.

The maximum spread width is determined by:

- Product type & integrity

- Product density

- Application rate

- Forward speed

- Wind speed and direction

- Disc height from crop canopy

SEED DEFLECTOR

An easily attached, optional adjustable deflector reduces and controls the spread width for products such as grass seed. Max spread width when fitted is 6m.

METERING MECHANISM

The fluted feed rollers supplied are suitable for most products from low to high rate applications. The rollers agitate the product to ensure a consistent flow. The feed roller meters product onto the spinning disc.

Alternative feed rollers are available for specialist pellets and seeds. These are easily changed to provide suitable application rates.

CALIBRATION HOPPER

An optional calibration aid, a steel chute is easily attached and collects and deflects the product being spread into a user provided bag for weighing during calibration checks. The calibration aid is supplied as standard with all i-CON models.

WATERPROOF COVERS

Fan Jet’s can be supplied with optional waterproof covers for use when out of work.

BUILT IN THE UK

Wisbech is still the home of Stocks Ag. All applicators are fabricated, assembled and painted in the Cambridgeshire factory. Precision assembly and quality control are paramount to the production process.

The R & D team work with both the factory and farmers to deliver a seeding solution that is fit for current farming practices.

Share via WhatsApp

Share via WhatsApp