The Maxi Jet is capable of delivering product up to 15m working width. Seed is metered and blown out of either two or four 63mm diameter outlets. Flexible pipes are used to transfer the seed to distributor heads with 6, 8, 10, 12 or 16 outlets. Smaller diameter pipe is used to transfer seed to individual spreader plates. Hence, a Maxi Jet can distribute seed from 12 to 64 outlets.

Three different control systems can be specified; JACKAL, i-CON or ISOBUS, to suit operational requirements for precision. Machines come with a 240L hopper or a 400L hopper.

The Maxi Jet is a versatile and accurate pneumatic applicator and seeder. It can be fitted to a wide variety of machines to deliver product up to 15m working width. Typical host machines are grass harrows, cultivators and rolls but the Maxi Jet can be employed as an additional applicator on a grain drill.

When used for small seeds or granules the Maxi Jet can be calibrated to apply precise rates across a wide range of products from 1kg/ha to more than 200kg/ha (dependent on product, working width and forward speed). Commonly used for applying clover seed, full-rate grass reseeds and cover crops.

KEY FEATURES

-

Up to 15m working width

-

240 or 400 litre hopper

-

5m fused battery power cable and 5m connector and power cables

-

Agitator included as standard

-

Distribution/spreading kit included available as an option

-

Small or large seed and granular (e.g. Avadex) feed block kits available

CONTROL OPTIONS

Three systems are available JACKAL, i-CON or ISOBUS. The i-CON and JACKAL are supplied with a control console, connector cable and fused battery cable. ISOBUS units are supplied with 10m of fused battery cable. Extension cables are available as a cost option.

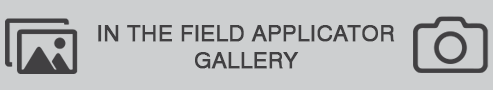

JACKAL CONTROL

The JACKAL is a simple compact controller which enables monitoring and adjustment of all key functions. Screen shows application rate, forward speed, hopper level alarm and fan voltage. As standard the forward speed input is taken from the tractor 7 pin implement socket.

The JACKAL can be fitted with a GPS speed input and in/ out of work cut-off switch if required.

- Simple accurate calibration for precise rate control.

- Forward speed adjusted rate control as standard speed input via tractors 7 pin implement socket.

- In cab application rate display, forward speed, area worked and hopper level sensor (if fitted).

- On the move rate adjustment, plus two “quick rate” functions keys for pre-set application rates (adjustable).

- High and Low alarm functions for metering roller.

- Large LCD screen, easily read characters contained in a robust housing.

- GPS forward speed sensor optional.

i-CON CONTROL

Rates are automatically controlled in proportion to forward speed for ultimate accuracy, and the machine can apply variable rates according to mapping data using a GPS based touch screen*.

*subject to unlock fee

GPS sensor, hopper level sensor and on/off finger switch supplied as standard.

- 4.3” colour touch screen with 4 basic menu keys

- Seed application rate kg/ha or seeds/m²

- Pre-start - ensures seed delivery begins as soon as the drill enters work

- Rate nudge – on the move adjustment in pre-set increments

- Min/max forward speed (km/h) indicator with alarms

- Metering unit status (on/off) and alarm

- Hydraulic fan speed and alarm

- Hopper contents (kg) and low level alarm

- Part, full job & grand totals for area (ha), product dispensed (kg) and hours worked

- ISOBUS compatibility kit available

ISOBUS CONTROL

Bridge module link to tractor ISOBUS available.

* ISOBUS screen not supplied, for illustrative purposes only.

- Controls multiple applicators as if they were on machine

- The tractors own GPS is used for a speed input

- The Task Controller can be used to control the applicator/s ON/OFF function

- Easily swapped between tractors

- Can control up to 4 machines

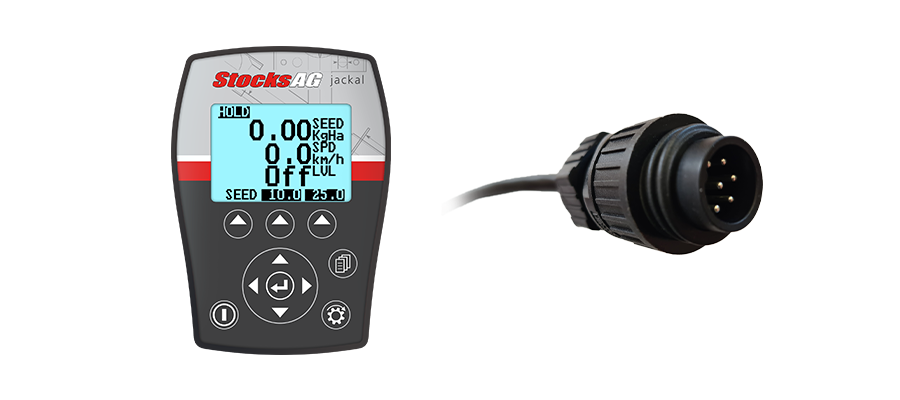

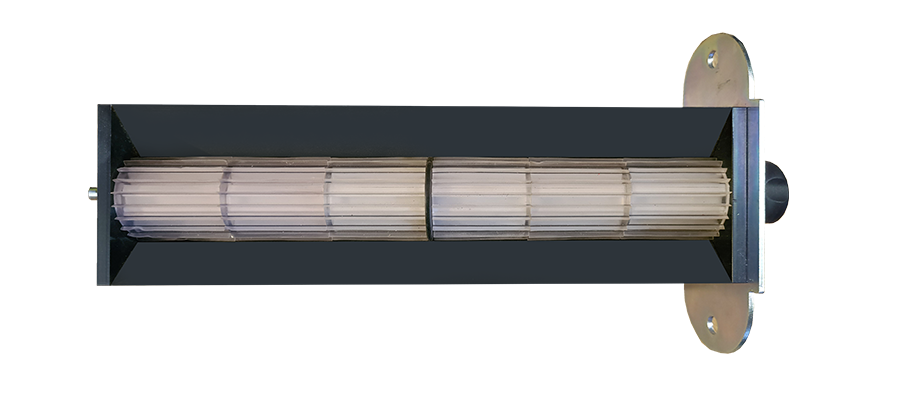

HYDRAULIC FAN

Turbo Jet 10 Hydraulic only

- Multi-blade 1400cfm output hydraulic fan

- Working width up to 15m

- Maximum airflow for high application rates and forward speeds

- Fan speed monitoring and control box alarm

- Mesh intake guard to prevent blockages

- Oil required 27L/min - 65L/min

- Dimensions: 49mm x 74mm x 19mm

- 100mm (4”) outlet

- Separately mounted and connected by a length of flexible hose

- Pair of 5m hydraulic hoses provided

WORKING WIDTH

Working width is largely determined by the number of outlets, 2 outlet manifold machines are recommended for a maximum of 8m working width. A 4 outlet manifold machine is best above 8m and up to 15m.

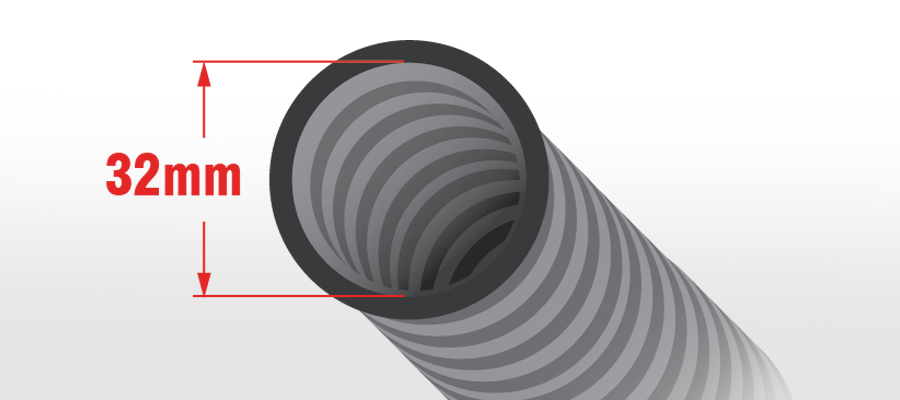

SEED HOSE

The internal diameter of the seed hose is 32mm, considerably greater than most alternatives. A wider diameter hose reduces back pressure and improves air flow, enabling higher application rates at higher forward speeds. A wider diameter hose also reduces the risk of blockages.

DISTRIBUTION HEADS AND RISER PIPE

Distribution heads then divide the seed evenly between 6, 8, 10, 12 or 16 outlets and seed is delivered using 32mm pipes on 6 outlet heads and 25mm pipes on 8, 10, 12 & 16 outlet heads.

In order to evenly distirbute seed from the distribution head a ribbed riser pipe is used in conjunction with high airflow from the hydraulic fan.

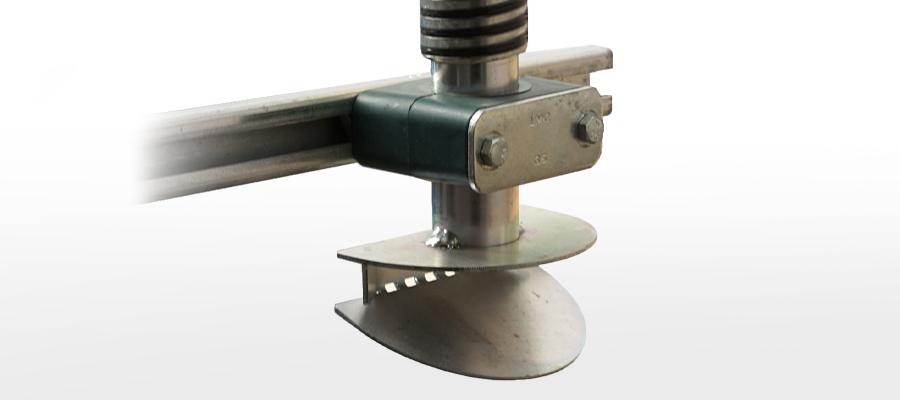

OUTLET SPREADER PLATES

- Robust design prevents spreader plate distortion.

- Provides a consistent even spread pattern.

- Secure attachment to mounting rail and seed hose.

- Adjustable bottom plates allow both band sowing and broadcast sowing.

METERING MECHANISM

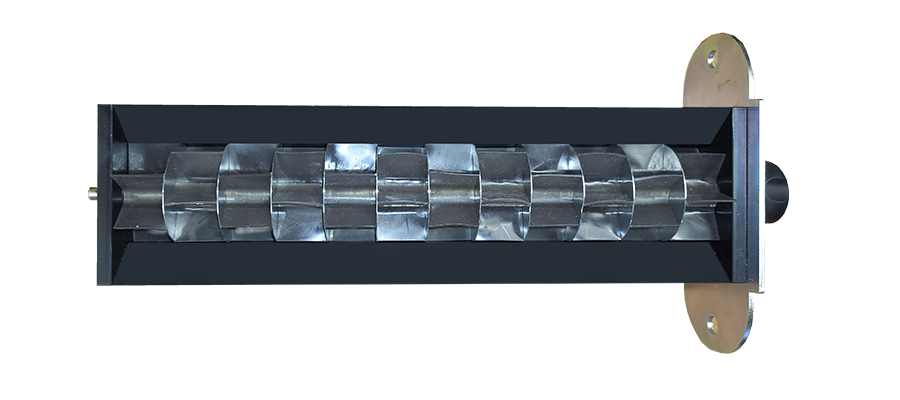

Fluted feed rollers on a stainless steel shaft are driven by a 12 volt electric motor. All Maxi Jets are offered with a choice of feed blocks.

Feed blocks are easily removed from the machine body. A variety of feed roller segments can be supplied, allowing multiple configurations to suit a wide range of applications. They are easily changed as required.

Calibration

An external calibration button is fitted as standard to enable the operator to start the calibration at the side of the machine.

A simple ‘catch and weigh’ calibration test establishes application rate. A calibration tray is supplied.

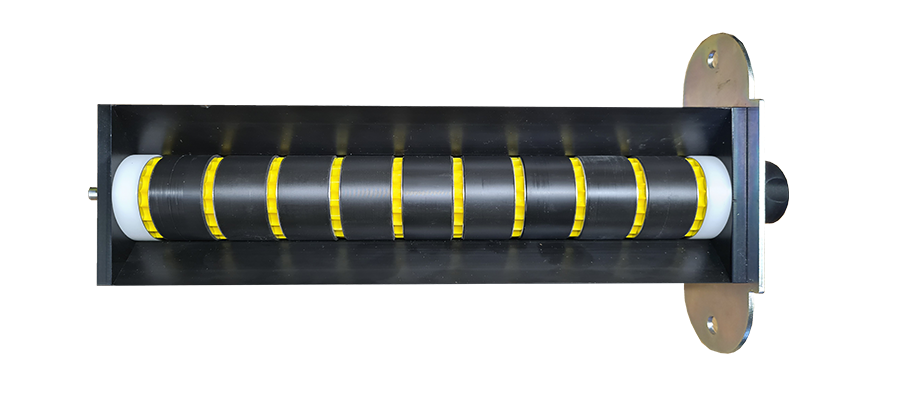

SMALL SEED FEED BLOCK

Individual feed rollers for each outlet ensure accuracy down to very low rates.

Typically used for OSR, clover, mustard, turnips and slug pellets.

LARGE SEED FEED BLOCK

50mmØ large feed rollers are supplied to meter high rates of both large and small seeds.

Typically used for grass and cover crops at e.g. 40 kgs/ha at 6m wide at 12kph.

A 59mmØ high capacity feed block is also available for the Maxi Jet. Typically used for wide machines, high rates and high forward speed applications. e.g. 100kg/ha, 6m wide at 15kph.

GRANULAR FEED BLOCK

Typically used for granular products e.g. Avadex.

MAXI JET SPECIFICATIONS

| MAXI JET | ||

| Control system | JACKAL | i-CON |

| Number of 63mmø outlets | 2 or 4 | 2 or 4 |

| Maximum working width | up to 15m | up to 15m |

| Hydraulic fan | YES | YES |

| Colour touch screen control box | - | YES |

| LCD display with push buttons | YES | - |

| Hopper agitator | YES | YES |

| Distribution/spreading kit optional | YES | YES |

| Calibration tray | YES | YES |

| Hopper capacity (Litre) | 240/400 | 240/400 |

| Choice of feed block | YES | YES |

| Number of distributor outlets | 12-64 | 12-64 |

| Forward speed sensor kit | Option | Option |

| Forward speed using tractor implement plug | YES | - |

| Forward speed GPS | Option | YES |

| Precision farming/variable rate | - | Option |

| In/out work sensor/switch | Option | YES |

| Hopper level sensor | Option | YES |

| Hopper cover | Option | Option |

| Weight 240L (400L) | 136kg (146kg) | 120kg (130kg) |

| Dimensions 240L (400L) - W x D x H | 65 x 130 x 109 (136cm) |

65 x 130 x 109 (136cm) |

| Paint to match host machine | Option | Option |

Supplied with:

5m fused battery power cable and 5m connector and power cables from console to Maxi Jet. Plus extension cables as a cost option.

Power requirement:

12 volts DC – 30 amps.

Due to our company policy of continual improvement we reserve the right to change specifications without notice. E & OE.

BUILT IN THE UK

Wisbech is still the home of Stocks Ag. All applicators are fabricated, assembled and painted in the Cambridgeshire factory. Precision assembly and quality control are paramount to the production process.

The R & D team work with both the factory and farmers to deliver a seeding solution that is fit for current farming practices.

Share via WhatsApp

Share via WhatsApp